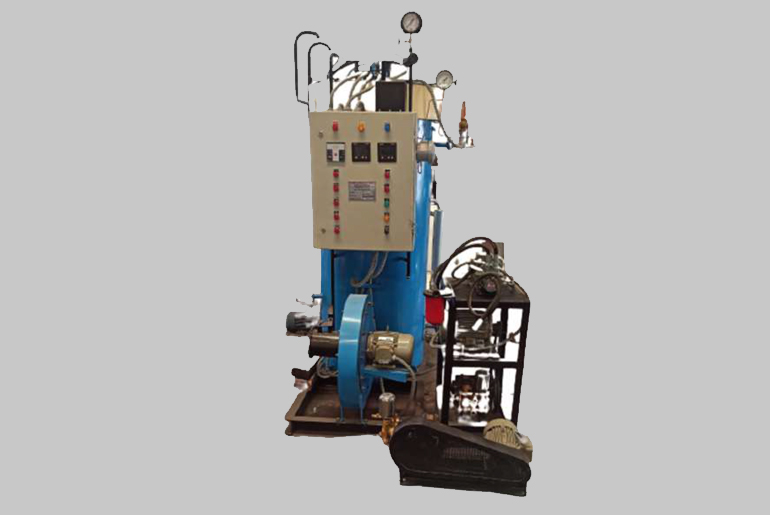

Being one of the reputed companies, We Offer Ibr Steam Boilers, Non- Ibr Steam Boilers, Industrial Ibr Steam Boilers, Industrial Non-Ibr Steam Boilers, Thermic Fluid Heaters, Hot Water Generators, Hot Air Generators, Thermic Fluid Oil in Hyderabad Telangana India. Ibr Steam Boilers are an essential part of many industrial and commercial operations. Ibr Steam Boilers are used to generate steam for a variety of uses, including heating, sterilization, and power generation. These Ibr Steam Boilers are known for their reliability and efficiency, making them a popular choice for many businesses and factories. An Ibr steam boiler is designed to fire a variety of fuels, including natural gas, propane, and oil. It is engineered to efficiently produce steam and to provide high levels of safety. The boiler is also designed to meet strict international safety standards, such as those set by the International Boiler Regulations (IBR). This ensures that the boiler is safe and efficient.

The Ibr Steam Boiler typically consists of a tank, a burner, and a heat exchanger. The tank is used to store the fuel and the burner is used to ignite the fuel and create the steam. The heat exchanger is used to transfer the heat from the flame to the water or other fluids. The boiler is also equipped with safety features, such as pressure and temperature sensors, to ensure the safety of the system.The efficiency of an Ibr steam boiler is determined by its design. The boiler must be able to produce steam quickly and efficiently while still remaining safe. Many boilers are equipped with advanced technologies, such as automatic fuel feeding systems, that help ensure the boiler is running efficiently.The main benefits of using an Ibr steam boiler include its reliability, efficiency, and safety. It is also a relatively low-cost solution for many businesses and factories. The boiler is often used as a reliable source of energy for a variety of applications.

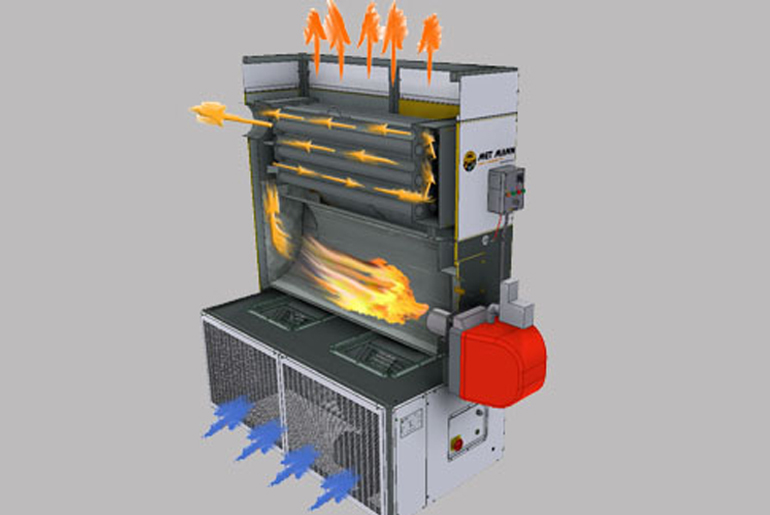

Non IBR Steam Boilers Manufacturers in India

Non IBR Steam Boilers are an efficient and economical solution for meeting the steam requirements of a variety of industries. These Boilers are designed to provide a safe, efficient, and reliable source of steam for a variety of industrial applications. Non IBR Boilers are typically used in industries such as food and beverage, pharmaceutical, and automotive manufacturing. Unlike other types of boilers, these Non IBR Steam Boilers do not require an engineer to certify the design of the boiler, nor is there any need for an IBR license. This makes them cheaper to install, operate, and maintain than IBR boilers. Non IBR Boilers are highly efficient and can be used to generate steam for a variety of industrial applications. Non IBR Boilers are generally used for steam generation for high-pressure applications, such as steam cleaning, steam curing, and steam distillation. These Non IBR Boilers are also suitable for applications that require low-pressure steam, such as sterilization and food processing. Non IBR Boilers are typically designed with a single-pass design, which means they are relatively simple in design and operation. This gives them a number of advantages, such as their low cost and high efficiency. Non IBR Boilers are also safer than other types of boilers, as they do not require a safety valve or other safety device. Non IBR boilers are available in a variety of sizes and configurations. This allows them to be used in a variety of applications, from small-scale industrial projects to large-scale industrial operations. Non IBR Boilers are also easy to install and maintain, making them an attractive option for many industries. Non IBR steam boilers are an efficient and economical solution for providing steam in a variety of industries. Non IBR Boilers are safe, efficient, and reliable, and are an attractive option for many industries.